Anti-siphon holes

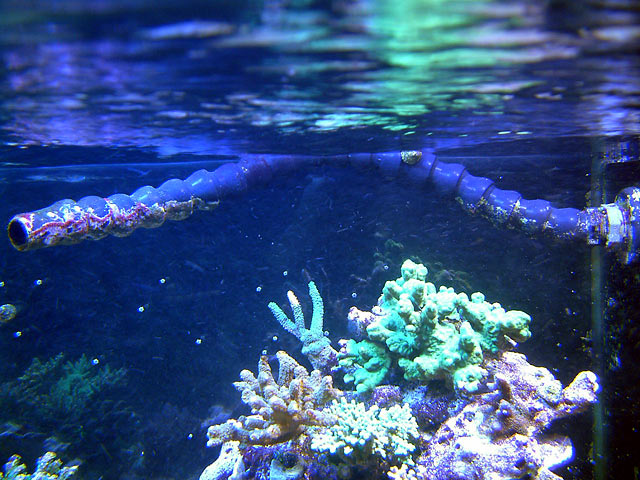

For a long time, I hated the returns on my tank. InterAmerican drills the return hole in the overflow box, below the teeth. On a larger tank like mine, a couple of inches equals a lot of water in the sump. So I solved it by adding twice as much locline, and had it shaped in an arch. At the apex of the arch, I drilled three holes in the underside to break the siphon and stop draining so much water. This worked great, until about 6 months ago when I soaked the locline in muriatic acid, which cracked the joints and allowed more water to seep out quietly.

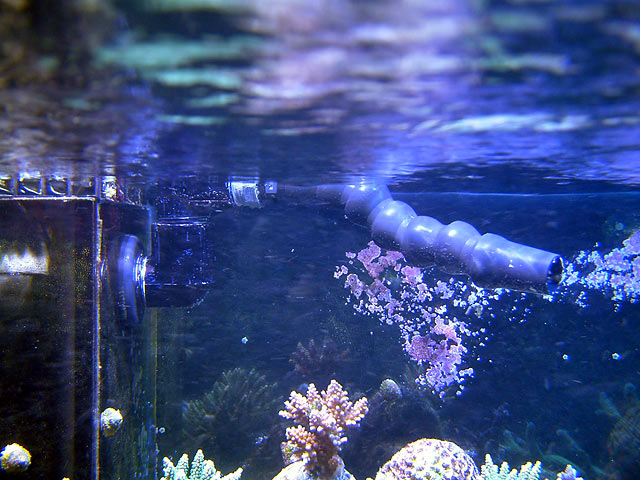

This is what it looked like (right side of tank):

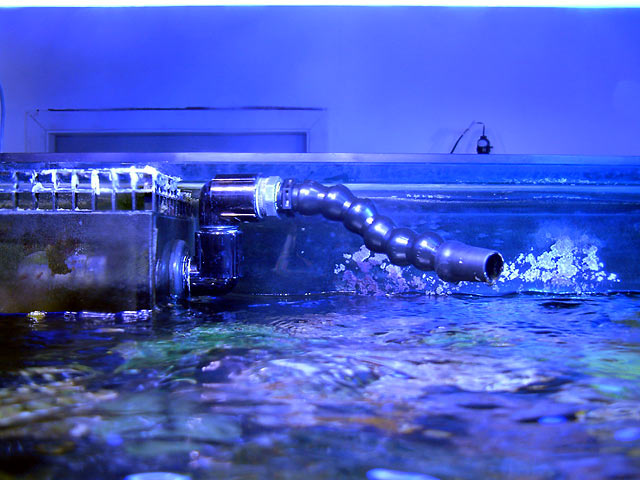

I replaced it with this today (left side of tank):

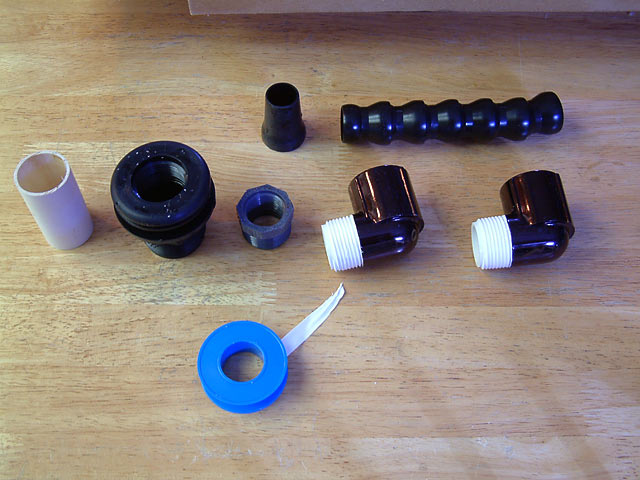

It was something I'd been wanting to do for a while. So here are the pieces. I used 1" PVC to help keep the flow unrestricted, even though I added two elbows doing this. However, I prefer this method to just going up over the top of the overflow, as that plumbing inside isn't glued and I don't want it blowing apart nor permanently glued inside.

The PVC parts were colored with a black Sharpie, which is reef-safe. Over time, even if it comes off coralline will cover it. Threads were covered with Teflon tape, with three or four full rotations (clockwise). When screwing in the fitting, the teflon should not peel off or unscrew off the threads. If it does, it was wrapped incorrectly.

Here is the layout for it to be assembled to fit my overflow.

Almost done.

Two anti siphon holes were drilled, which remain beneath the normal water level in the tank.

When the tank refills (return pump on), water squirts out the holes into the tank. This is a good way for you to verify they are not clogged. Remember, if your tank siphons too much water out, it could be that the holes are clogged and need to be cleared again.

Done. It looks so much better than before. When the return pump is off, the siphon is quickly broken and less water drains to the sump. :)

I made one for both sides of the tank, and it makes the reef look so much cleaner. The reason the bulkheads were removed for this project is because I was unable to screw in the new PVC fittings with them in place. There was no room for 360 degree rotations, so it was better to disassemble everything and pre-assemble them as a unit.

It only took me 1.5 years to finally get around to this modification. ;)